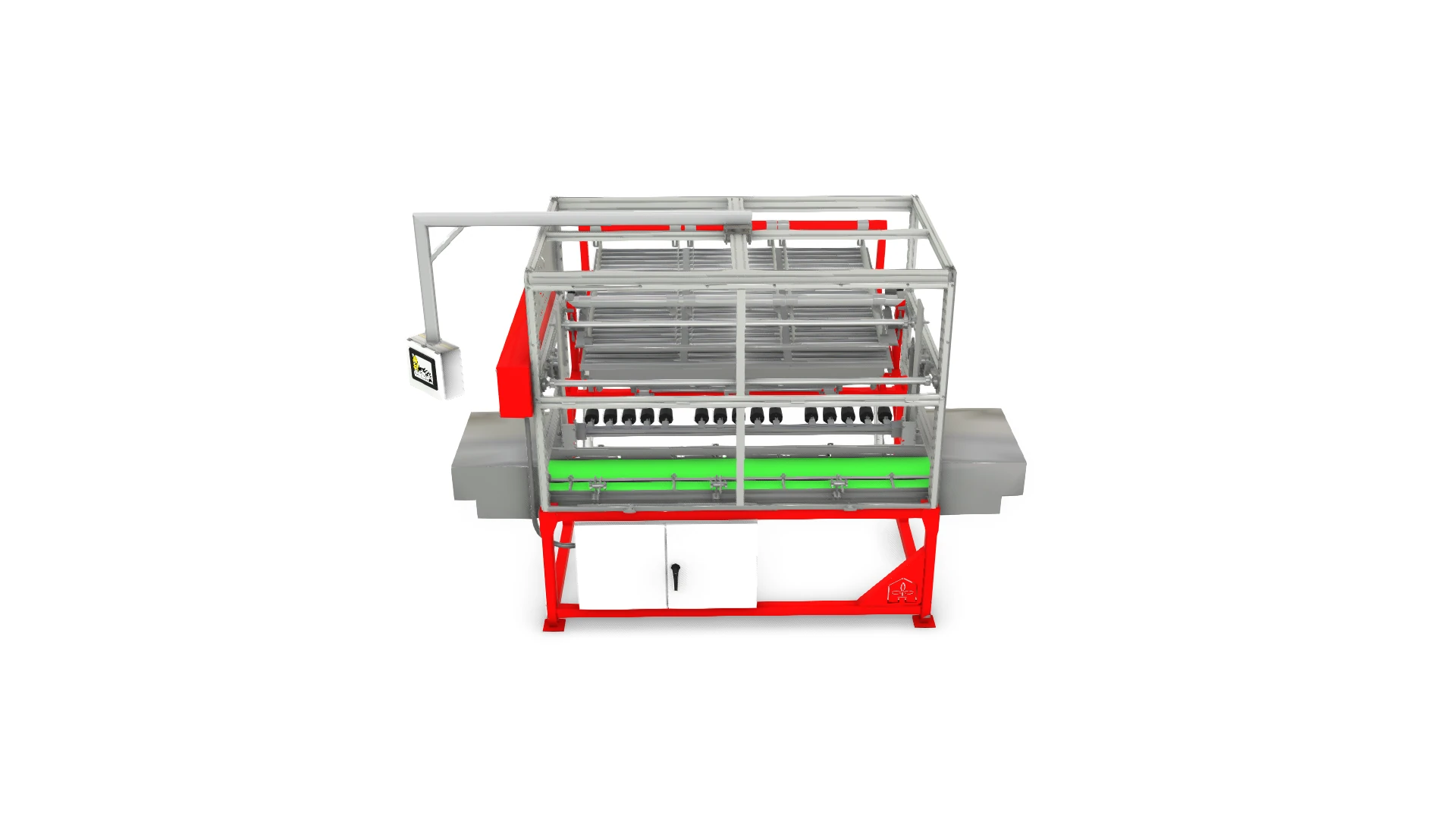

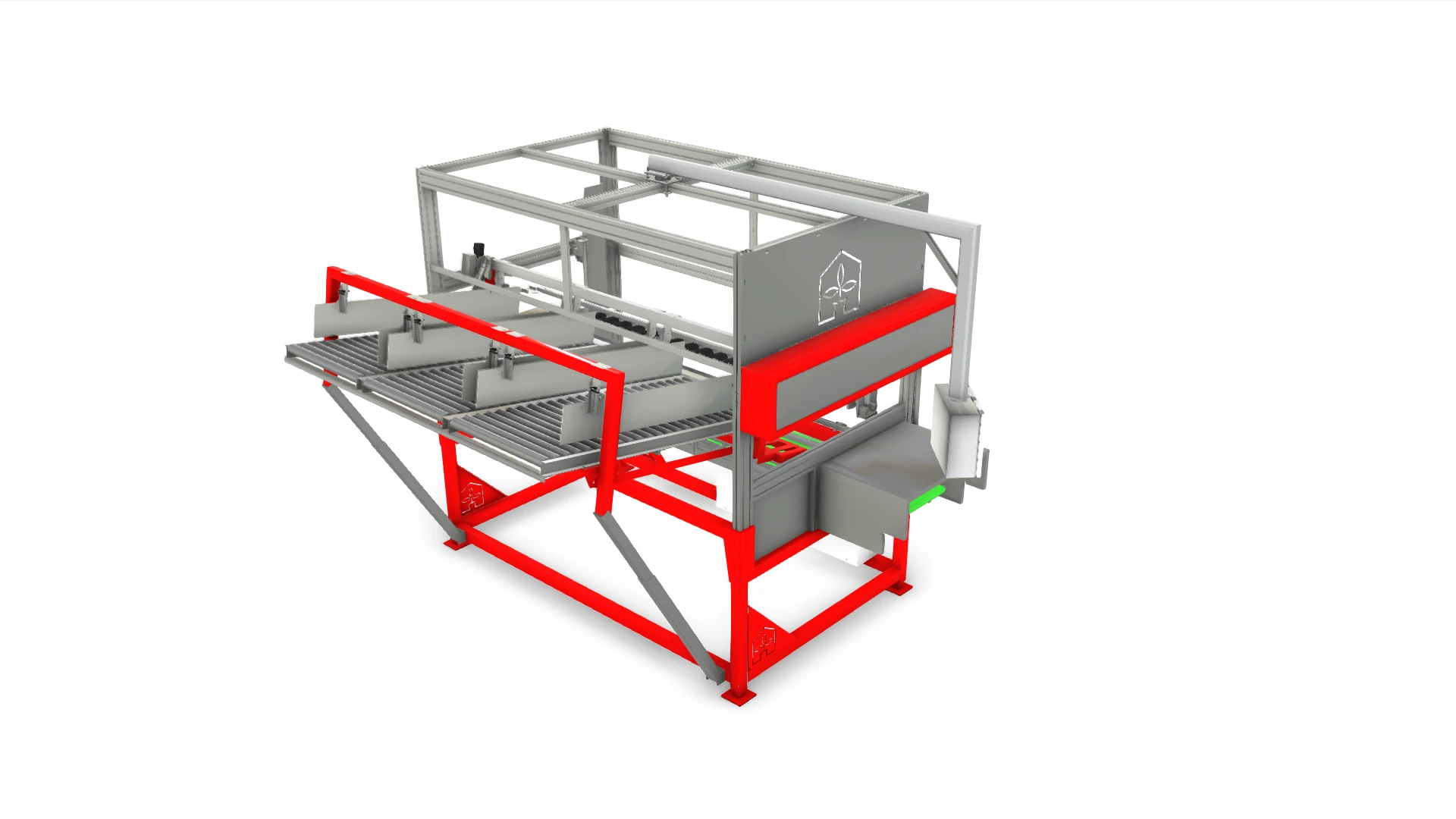

Introducing the PD-X3 Pot Dispenser: Precision, Speed, and Flexibility for High-Capacity Production Lines

The PD-X3 Pot Dispenser is a state-of-the-art solution designed to meet the needs of the most demanding production environments in the horticulture industry. Engineered with precision, speed, and flexibility in mind, this pot dispenser enhances your production capabilities and ensures that your operations run smoothly and efficiently.

Advanced Engineering for Optimal Performance

- High Capacity Output: The PD-X3 is exceptionally efficient, capable of filling up to 1,000 shuttle trays per hour and managing three shuttle trays simultaneously. This high output capacity is perfect for keeping pace with large-scale production demands.

- Cutting-Edge Motor Technology: Equipped with advanced servo and stepper motors, the PD-X3 offers superior control over speed, repeatability, and accuracy, ensuring that each pot is precisely placed every time.

- Versatility in Pot Sizes: This pot dispenser is compatible with both round and square pots. Thanks to its interchangeable pot holder sets, switching between different pot sizes is quick and straightforward, significantly reducing downtime and increasing operational flexibility.

- Ease of Use: Pots are conveniently loaded from the side, which not only simplifies the loading process but also enhances safety for operators. The inclusion of a 10-inch color touchscreen display makes the PD-X3 exceptionally user-friendly, allowing operators to easily select settings, make adjustments, and monitor the entire dispensing process.

Designed for Modern Horticultural Needs

The PD-X3 Pot Dispenser is not just a piece of equipment; it’s a comprehensive solution designed to integrate seamlessly into your existing production line. Whether you are dealing with thousands of plants or multiple pot sizes, the PD-X3 adapts to your needs, delivering consistent results every time.

Its robust construction and thoughtful design ensure that it can withstand the rigors of heavy-duty use, making it an invaluable asset for any grower looking to optimize their planting operations.

Upgrade your production line with the PD-X3 Pot Dispenser and experience a new level of efficiency and productivity. This fully programmable system is ready to take on the challenges of modern horticulture, providing you with the reliability and performance you need to succeed.