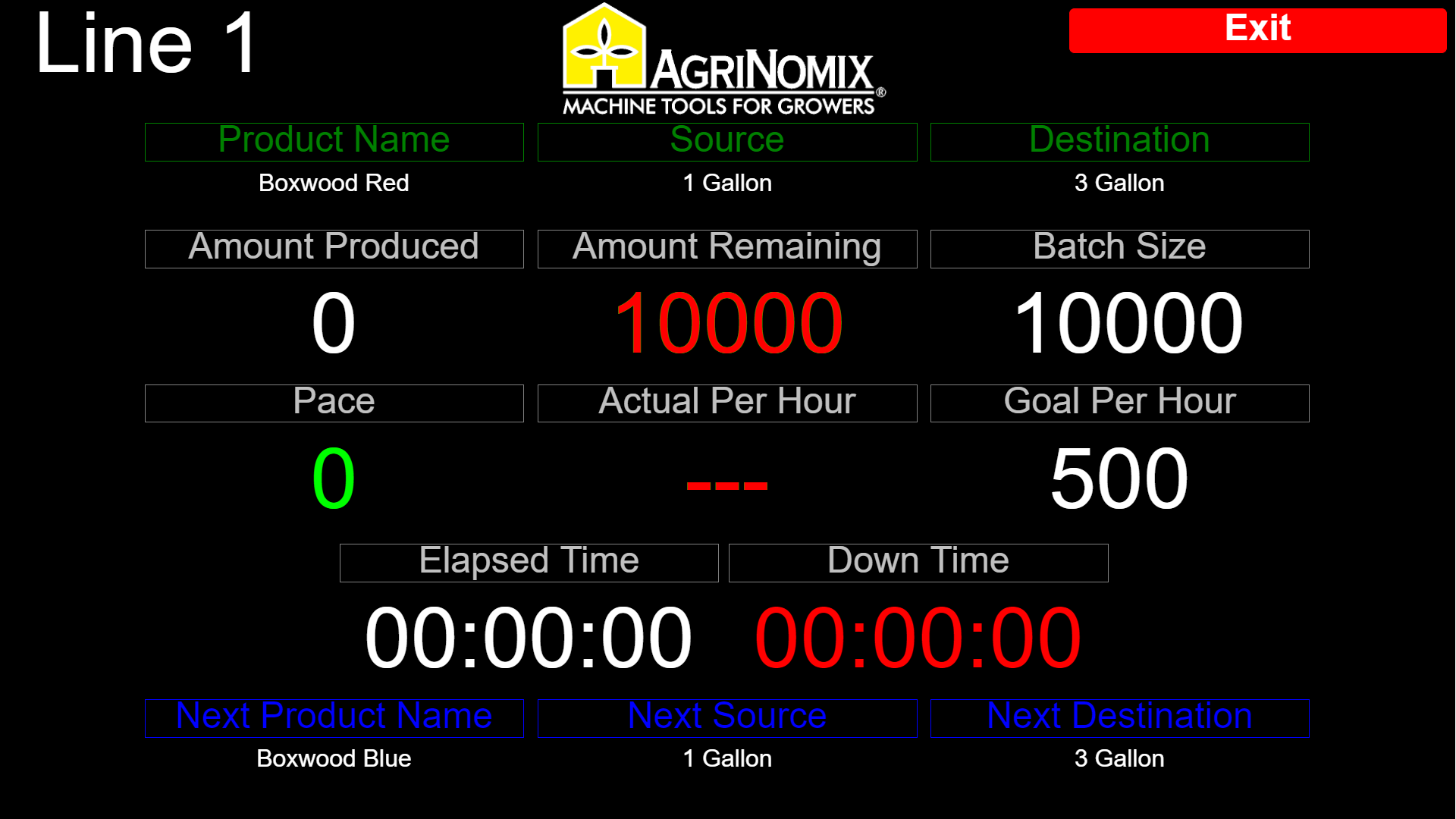

The value of a highly visible, real-time “Scoreboard” displaying production line performance against an established production rate is immense for any manufacturing operation. Our production pace timers system counts production in real time, instantly recalculating performance metrics and displaying results prominently on a large screen in the production area or on any workstation connected to the network.

This system serves as a powerful management tool by providing immediate insights into production efficiency, allowing managers to quickly identify and address any issues that may arise. The visibility of real-time data helps in maintaining consistent production standards and optimizing overall workflow.

Moreover, the scoreboard system acts as a motivational tool for workers. By clearly showing how the team is performing against targets, it encourages employees to stay focused and work efficiently to meet or exceed production goals. The transparency and immediacy of the data can lead to a more engaged and productive workforce.

In addition to real-time performance monitoring, the system also facilitates comprehensive data collection, providing an accurate record of what has occurred in every production run. This data is invaluable for analyzing trends, making informed decisions, and improving future production strategies.

Incorporating a real-time scoreboard system into your production line ensures enhanced productivity, greater worker motivation, and detailed performance tracking, all contributing to a more efficient and successful operation.