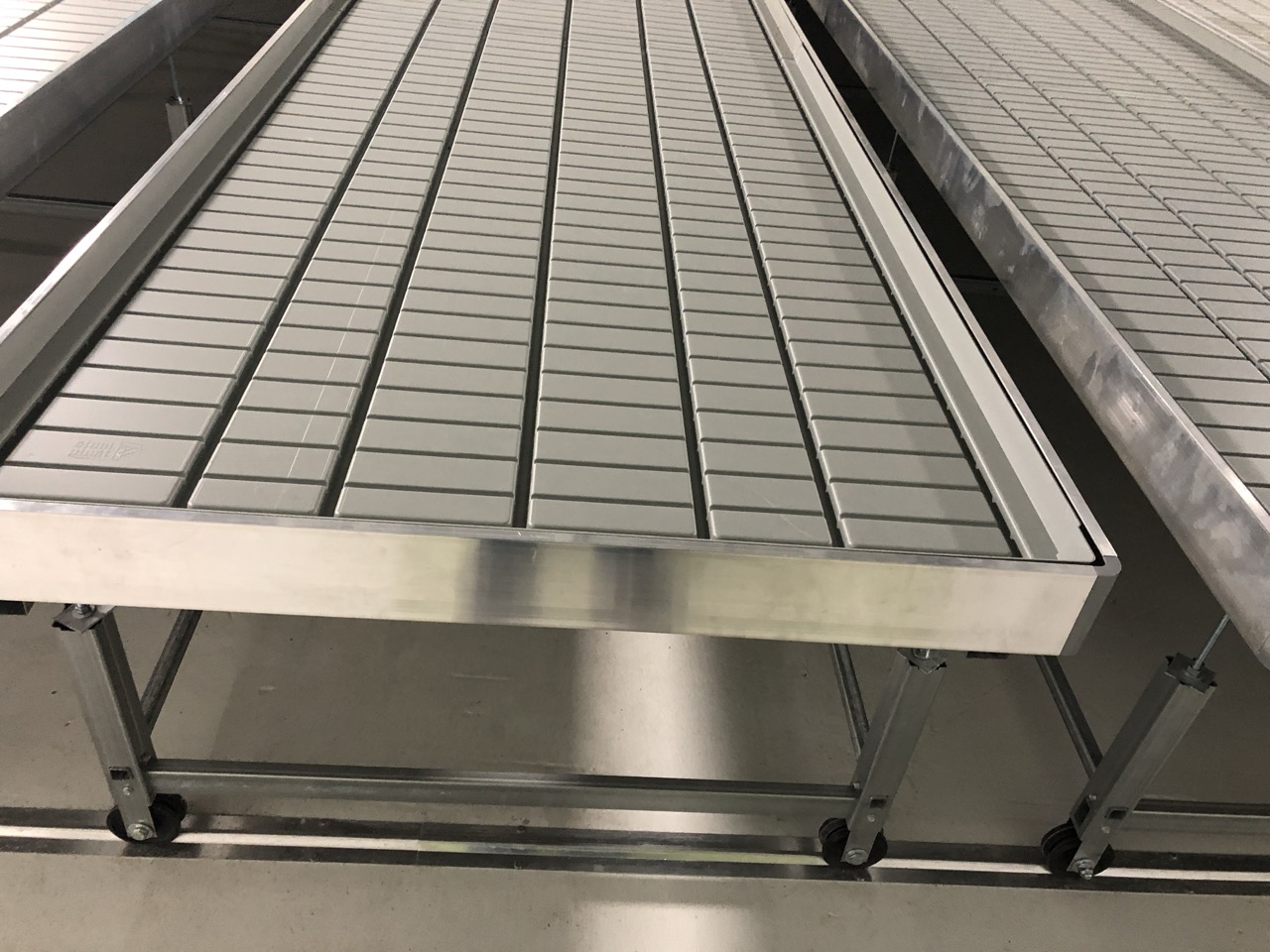

Container Conveyors

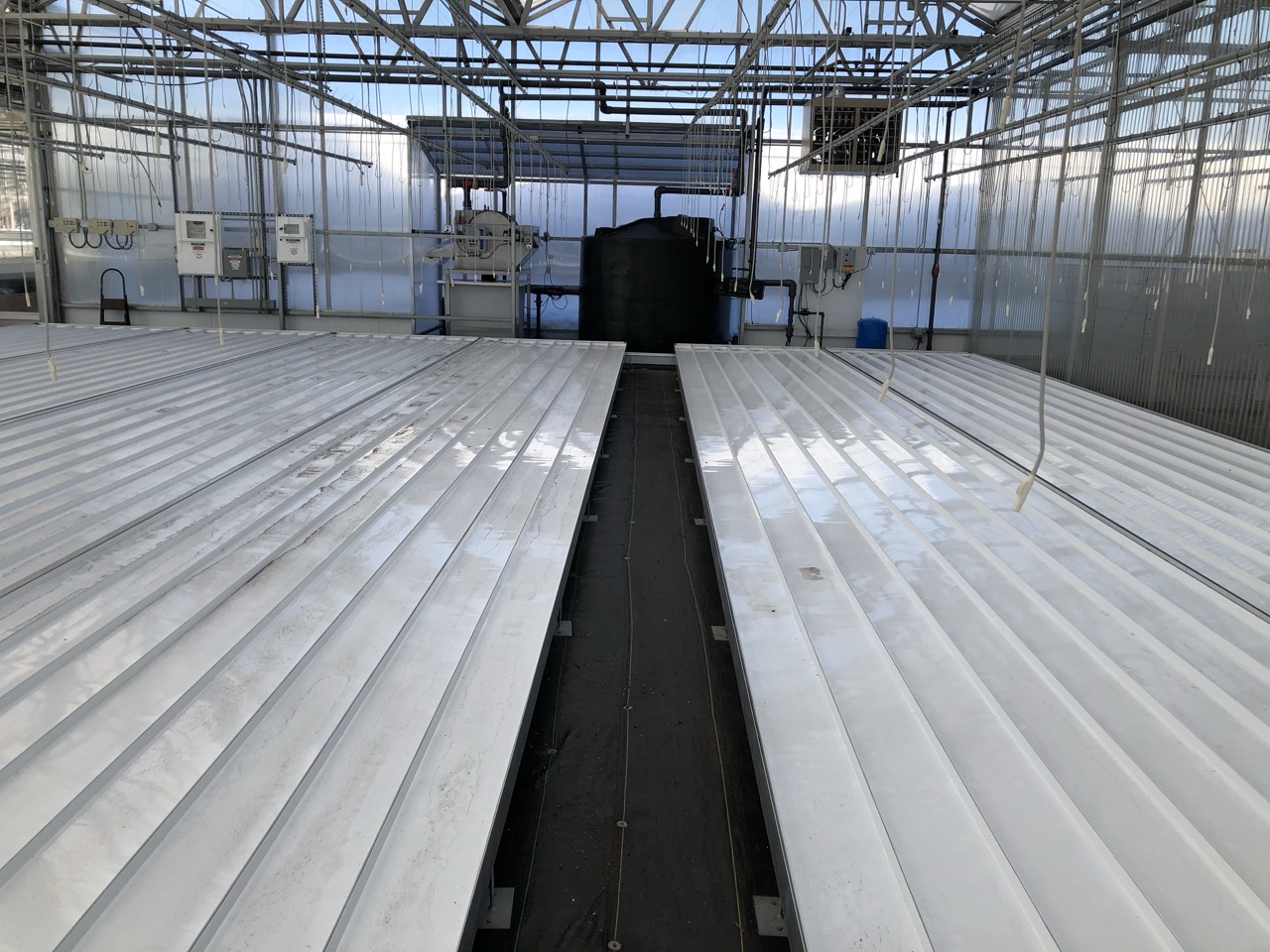

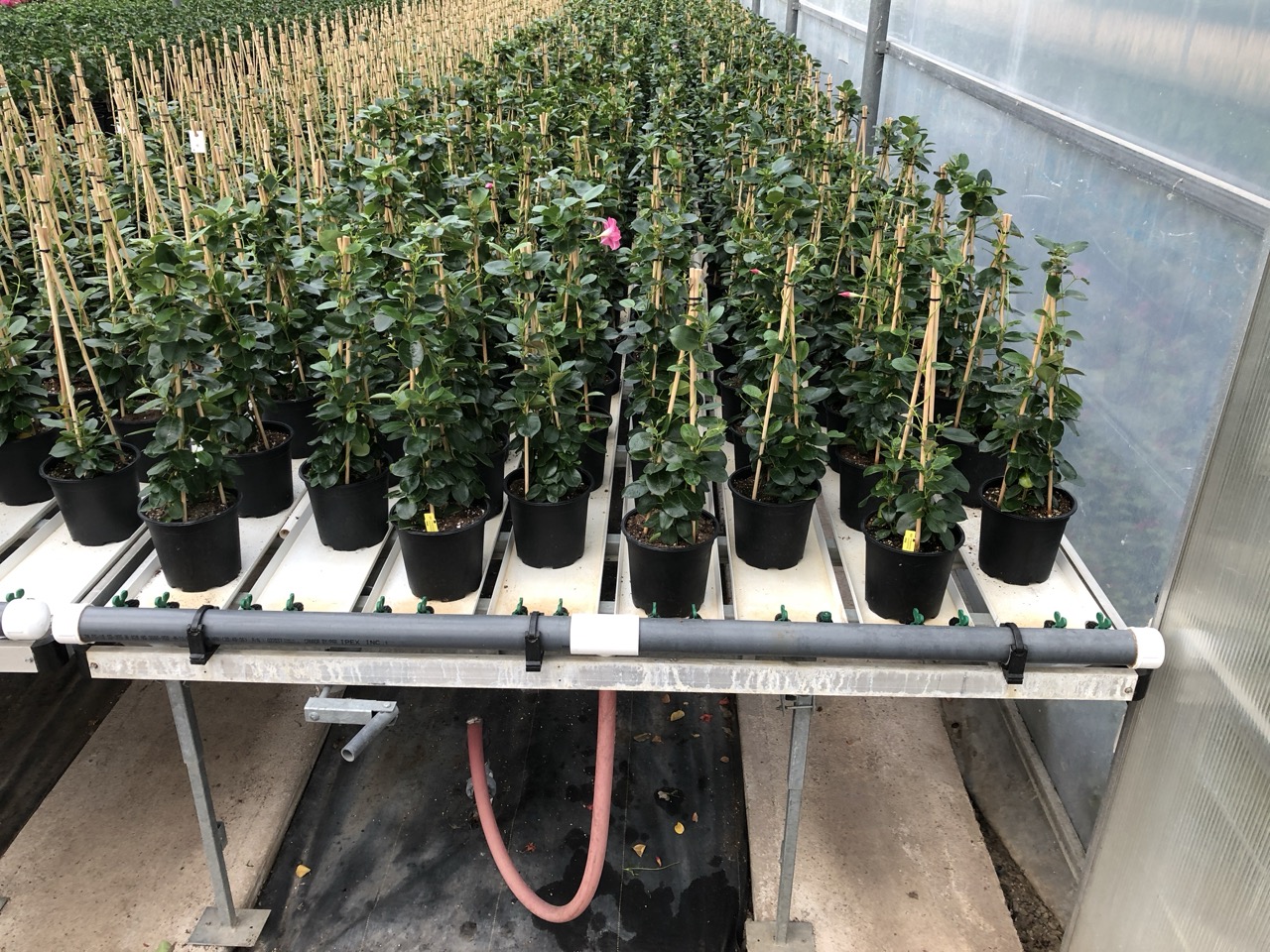

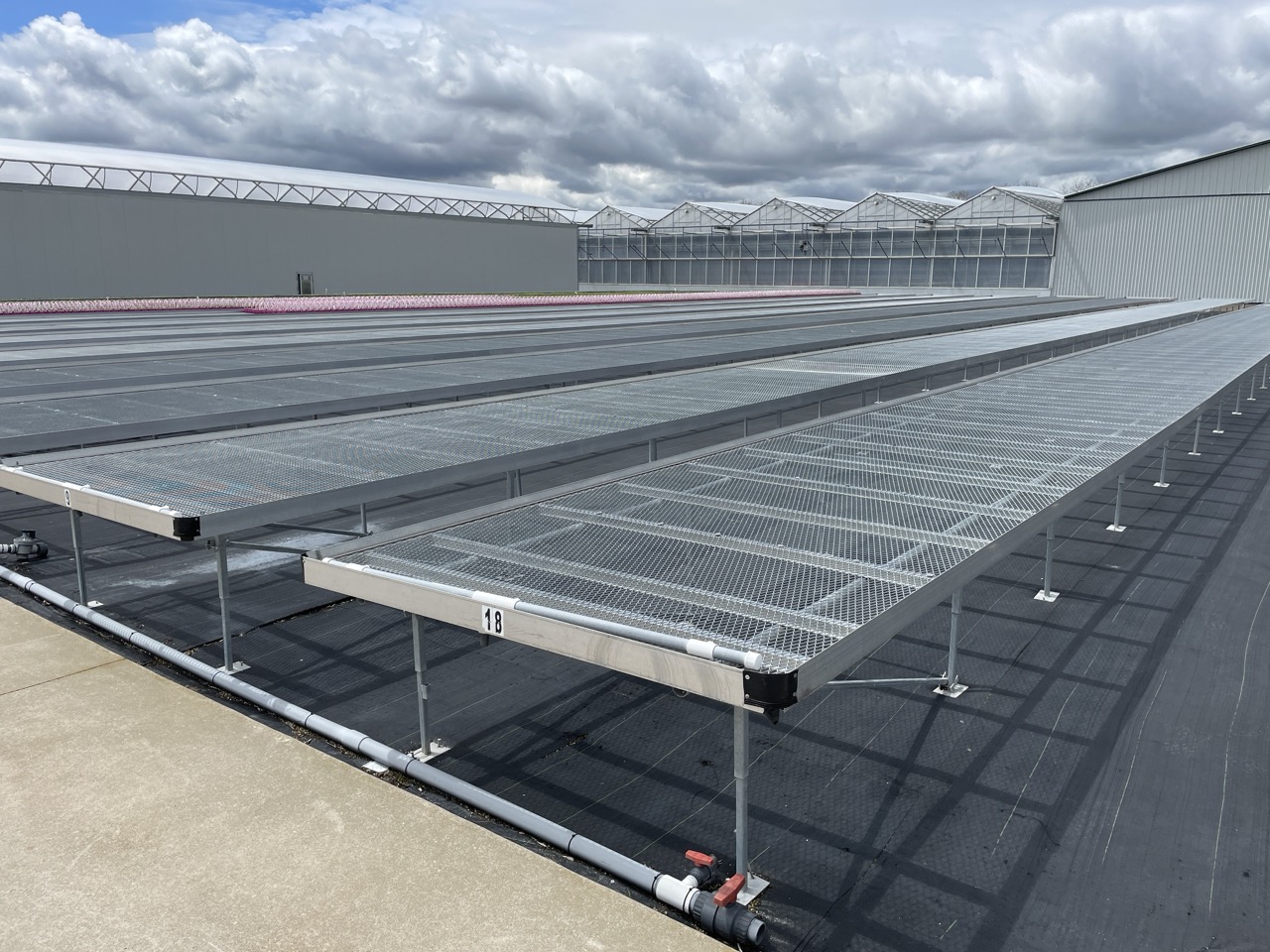

Movement of rolling benches on conveyors, commonly known as Rollabaans, can be managed manually or automatically via a computer-controlled drive system. This innovative solution offers significant labor savings by efficiently transporting plants between production, growing, and shipping areas using container conveyors. Rollabaans are the superhighways of the fully-automated greenhouse, streamlining operations and enhancing productivity.

The integration of computer-controlled drive systems with Rollabaans enables seamless automation throughout the entire growing cycle. These systems interface with production, grading, shipping, and environmental control systems, ensuring plants are moved automatically and precisely. This comprehensive automation minimizes manual handling, reduces labor costs, and enhances the overall efficiency of greenhouse operations.

Rollabaans provide a robust and reliable method for managing plant movement, supporting high-capacity operations with ease. The ability to automate the transport process allows greenhouse operators to focus on other critical tasks, optimizing workflow and improving productivity. By utilizing Rollabaans, growers can maintain consistent plant quality and ensure timely execution of production schedules.

Incorporating Rollabaans into your greenhouse setup transforms your operation into a high-efficiency, fully-automated system. This advanced technology not only boosts labor savings but also enhances overall operational efficiency, making it an indispensable tool for modern greenhouse management. Embrace the future of plant transportation with Rollabaans and experience the benefits of a streamlined, automated growing process.