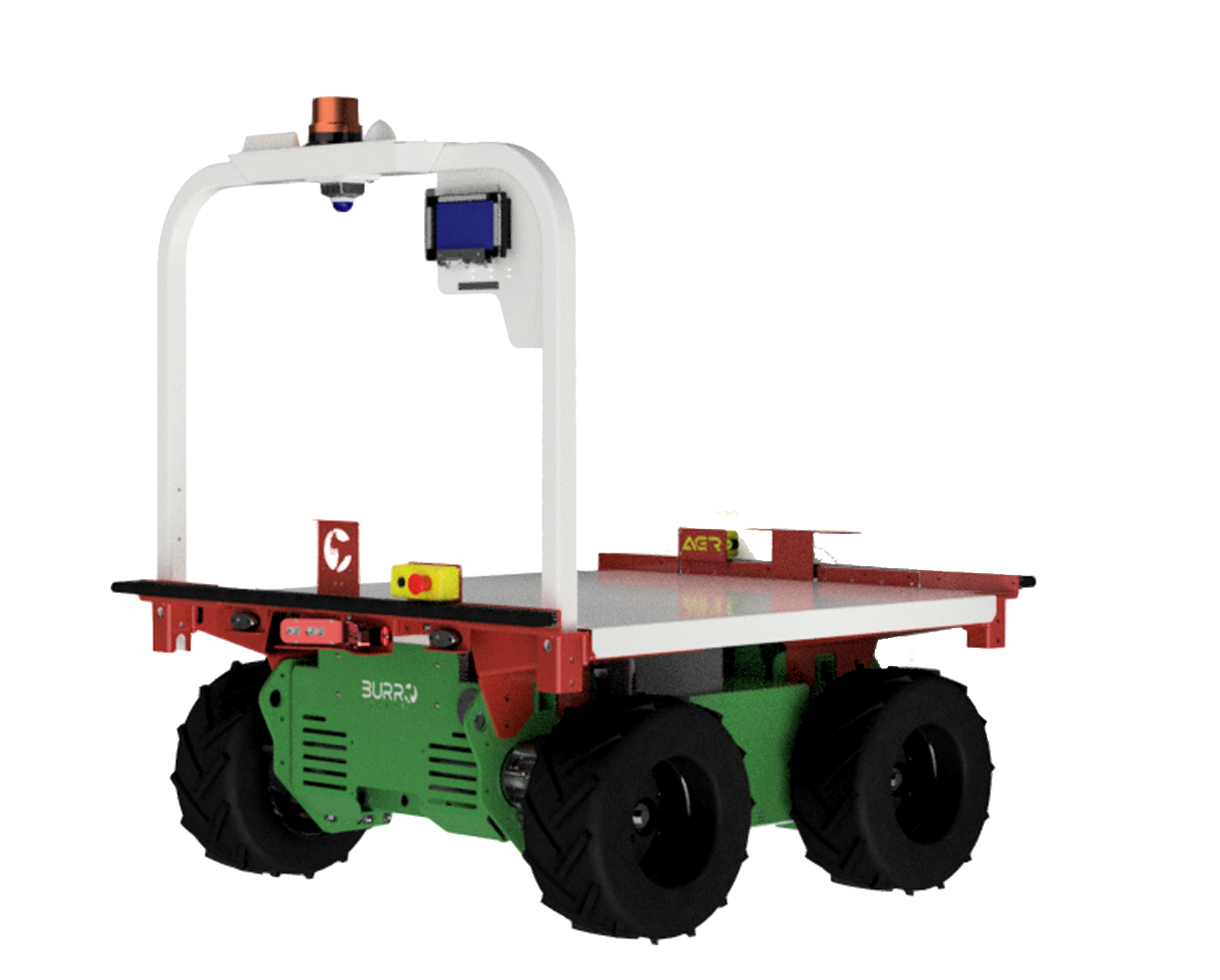

Heavy Duty Hook Shelf

The Heavy Duty Hook Shelf is a top choice for greenhouse growers needing a reliable cart for shipping over longer distances. This heavy-duty, durable design maximizes trailer space and includes warning signs and notification holders for added safety. Built-in hand grips ensure easy pulling, pushing, and steering, making it an efficient and practical solution for transporting plants and materials. Enhance your greenhouse operations with this robust and versatile cart.