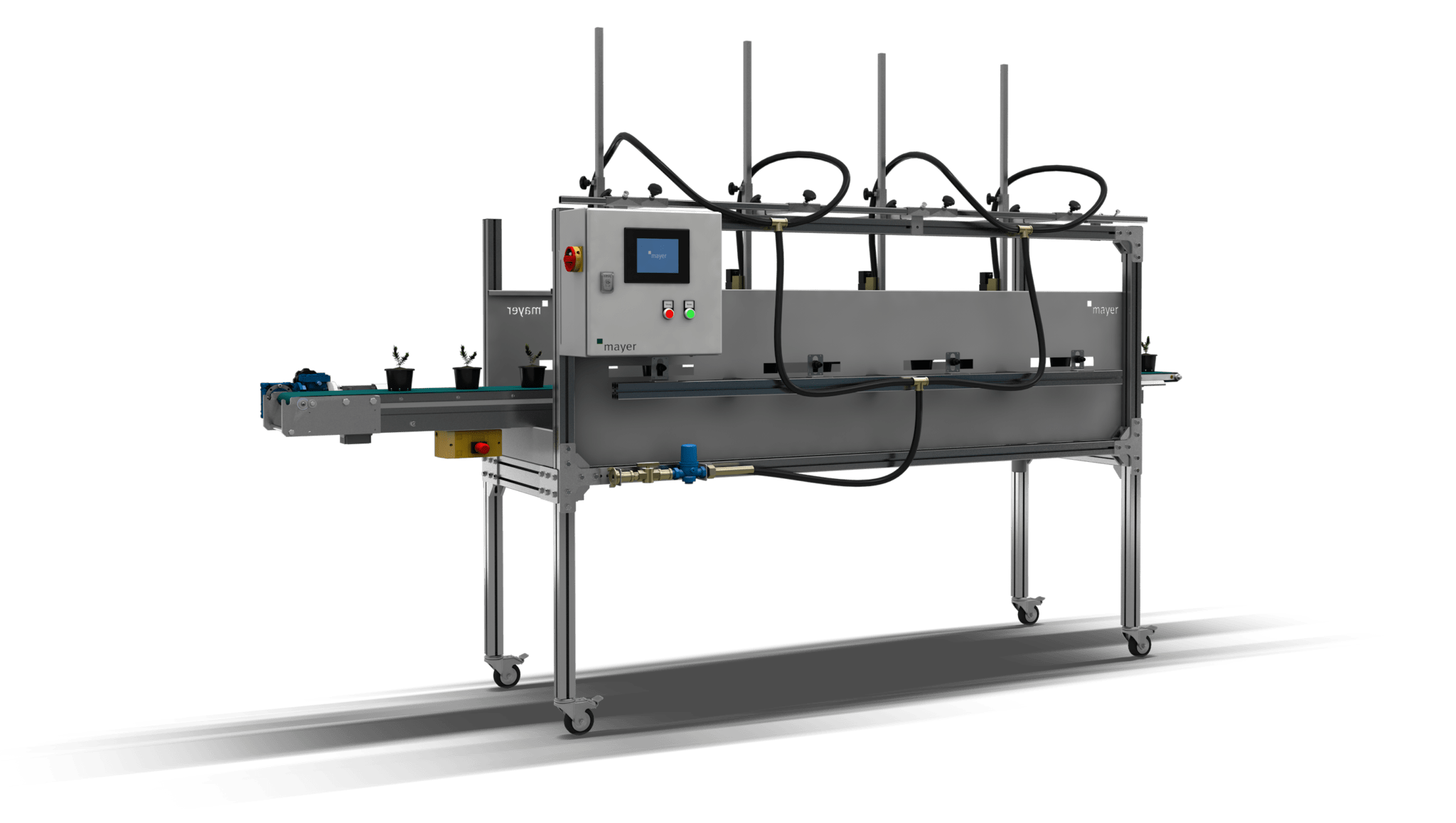

PD-X3 Pot Dispenser

The PD-X3 Pot Dispenser has been engineered to keep up with the highest capacity production lines. Advanced servo and stepper motors are employed for speed, repeatability, and accuracy. This fully programmable pot dispenser is capable of filling 3 shuttle trays at once, up to 1,000 shuttle trays per hour. and works with round and square pots. Not only is it fast, but it is also very flexible. Interchangeable pot holder sets are easily swapped out for different-sized pots, making changeovers simple and fast. Pots are loaded from the side instead of the top, which is much easier and safer. A 10″ color touchscreen display is user-friendly and easy to operate.