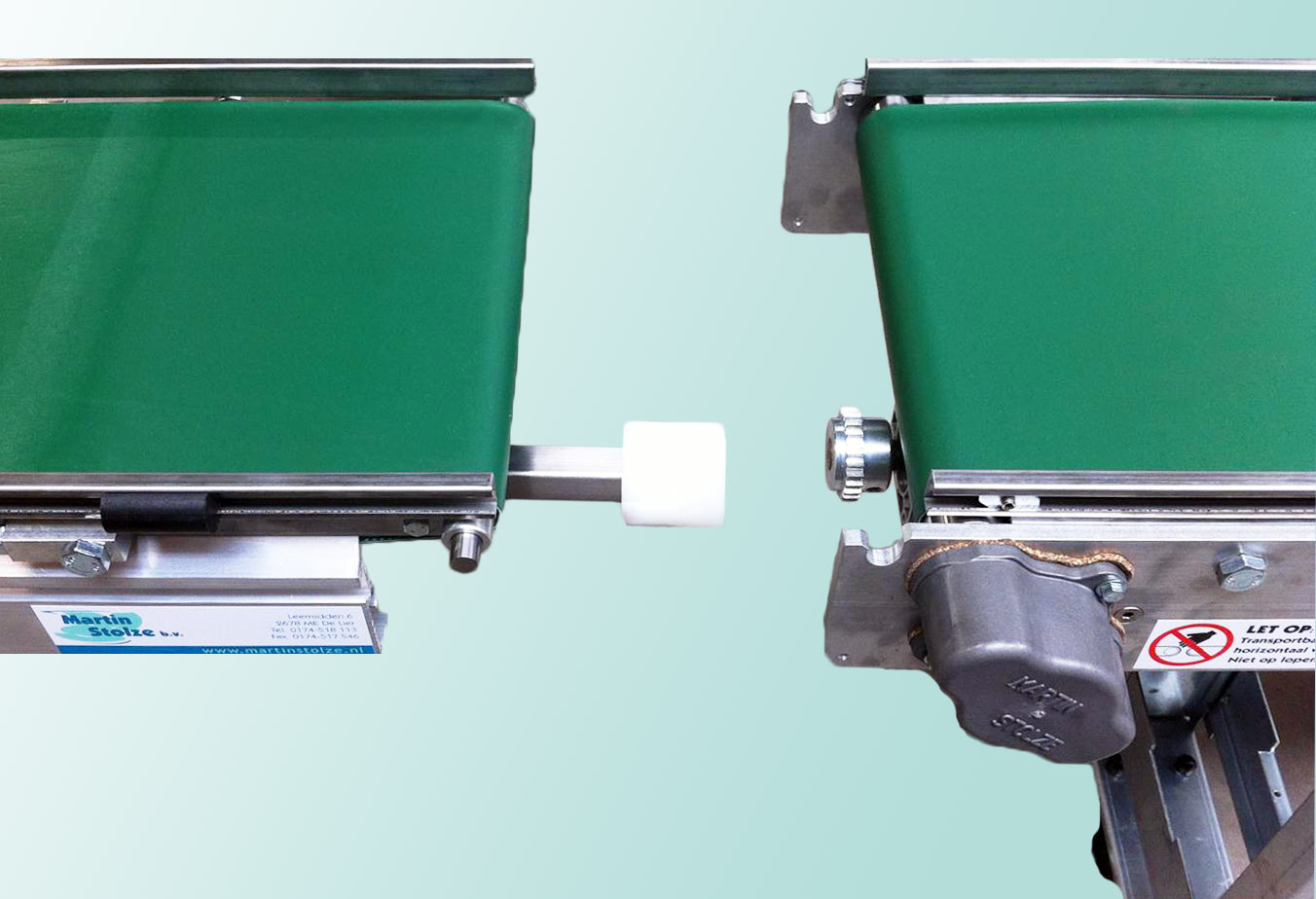

Production Line Conveyors

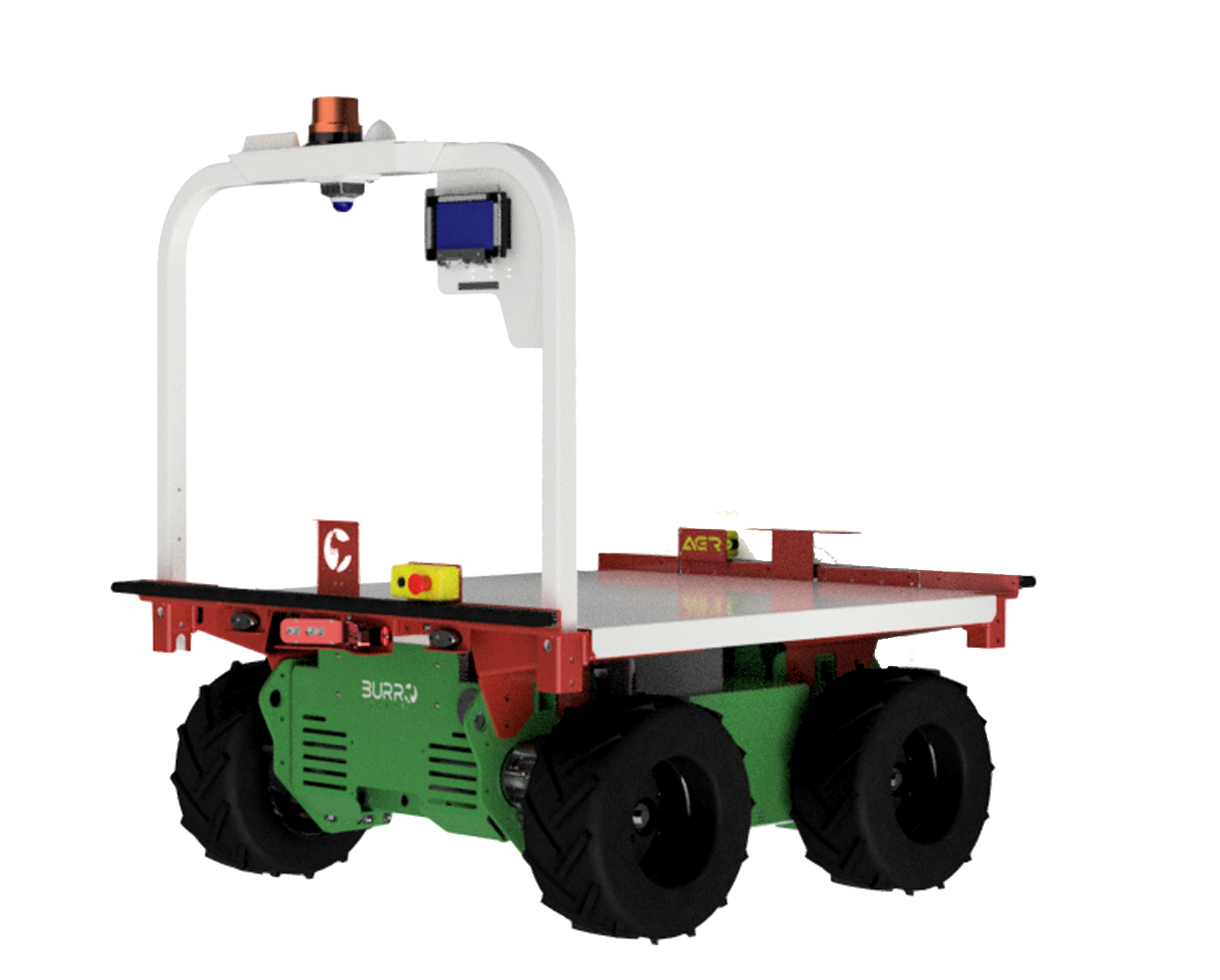

Production Line Conveyors are proven to significantly reduce material handling and increase productivity. They may be utilized to set the pace of a crew by bringing the work to the workers, verse moving your crew. These conveyors can be integrated into production lines to seamlessly move the product through the various tasks of production from the infeed to the take-off area. AdeptAg has a broad offering of conveyor lengths and widths to fit the various needs for the greenhouse and nursery industry.