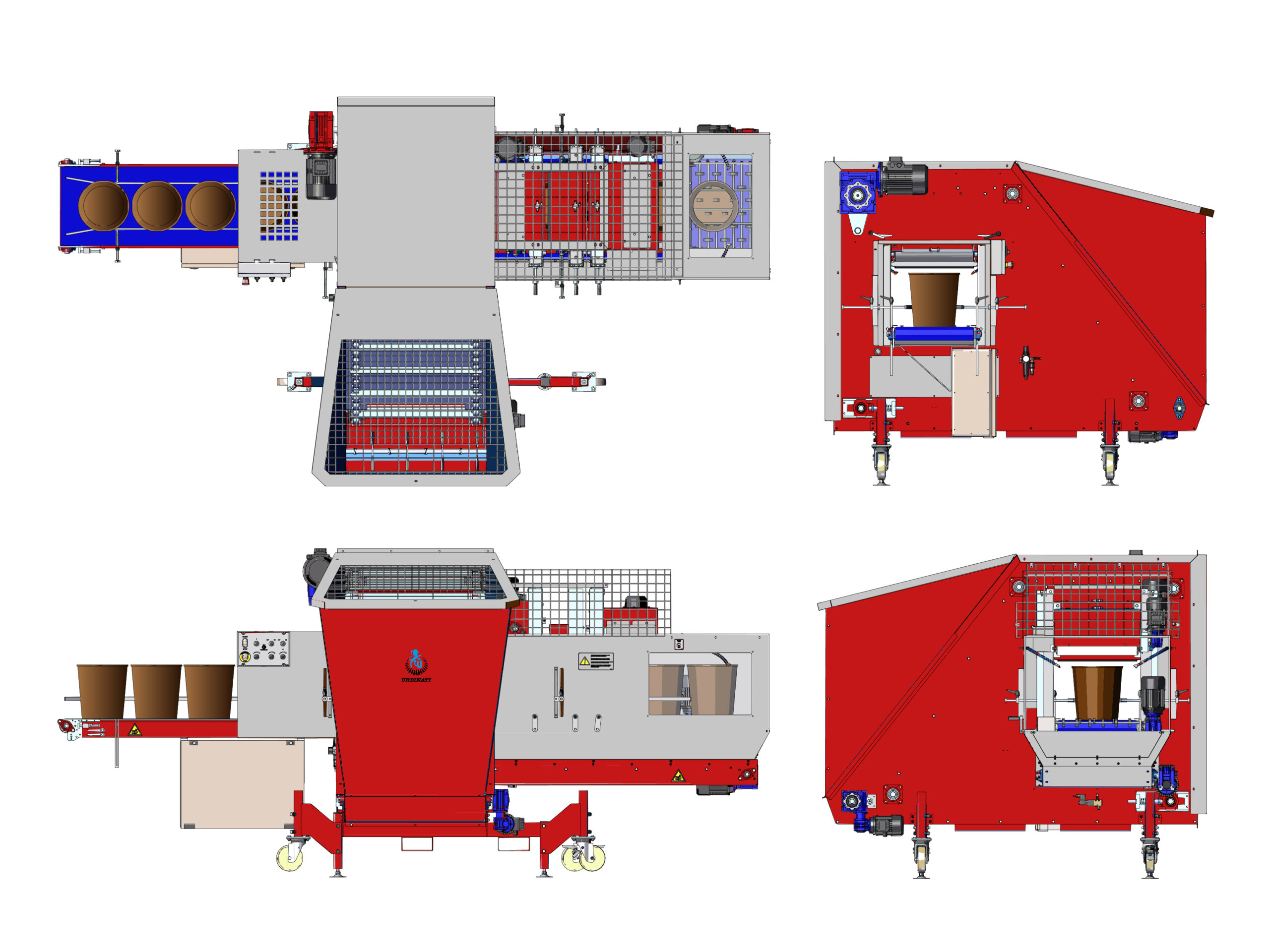

KV-XL Filler

The KV-XL Filler is the new standard for versatility and reliability in the industry. The design of this filler places the soil hopper directly over the filling belt ensuring even side-to-side container filling in a wide format and minimizes floor space usage. Direct drive gearboxes, inverter duty motors, sealed bearings, and heavy-duty galvanized & powder-coated steel construction provide for years of low maintenance operation.

Superior soil return capacity is achieved by using a large powered roller out-feed area, three belt conveyors, and a short, level auger at the top, that moves the soil sideways back into the supply hopper. Easy-to-use crank adjustments enable quick changeovers from one container to the next. Capable of filling any style container up 22” wide and 17-1/2” high.