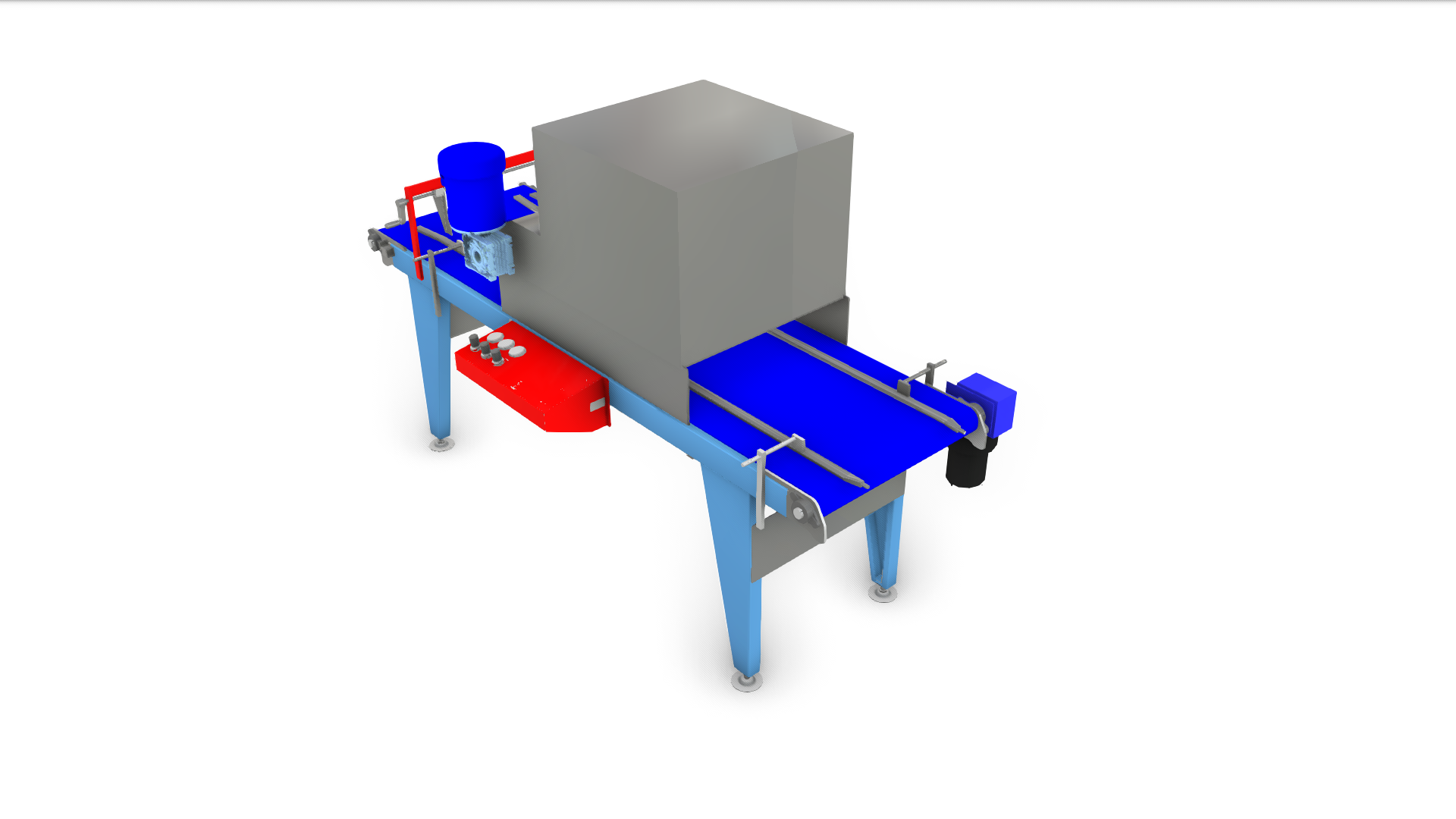

Soil Covering Unit

The Soil Covering Unit is an advanced solution designed to apply soil, sand, and other media to the tops of flats and pots. Mounted atop a 2.3-meter powered conveyor, it features variable speed controls to ensure precise application. This precision is further enhanced by a lift gate and the hopper’s variable speed grip belt conveyor, which together regulate the flow of media for customized coverage.

This unit significantly boosts efficiency by providing consistent and even distribution of covering material. This not only improves the overall quality of the planting process but also ensures that each pot and flat receives the optimal amount of media. Such consistency is crucial for promoting uniform plant growth and health.

Ideal for large-scale operations, the Soil Covering Unit streamlines workflow, making the entire process more efficient and less labor-intensive. By reducing the need for manual labor, it allows staff to focus on other critical tasks, thereby enhancing overall productivity. Its robust design and reliable performance make it a valuable addition to any horticultural setup, ensuring that growers can achieve high-quality results with minimal effort. The Soil Covering Unit is an essential tool for modern growers aiming to optimize their planting processes and improve operational efficiency.