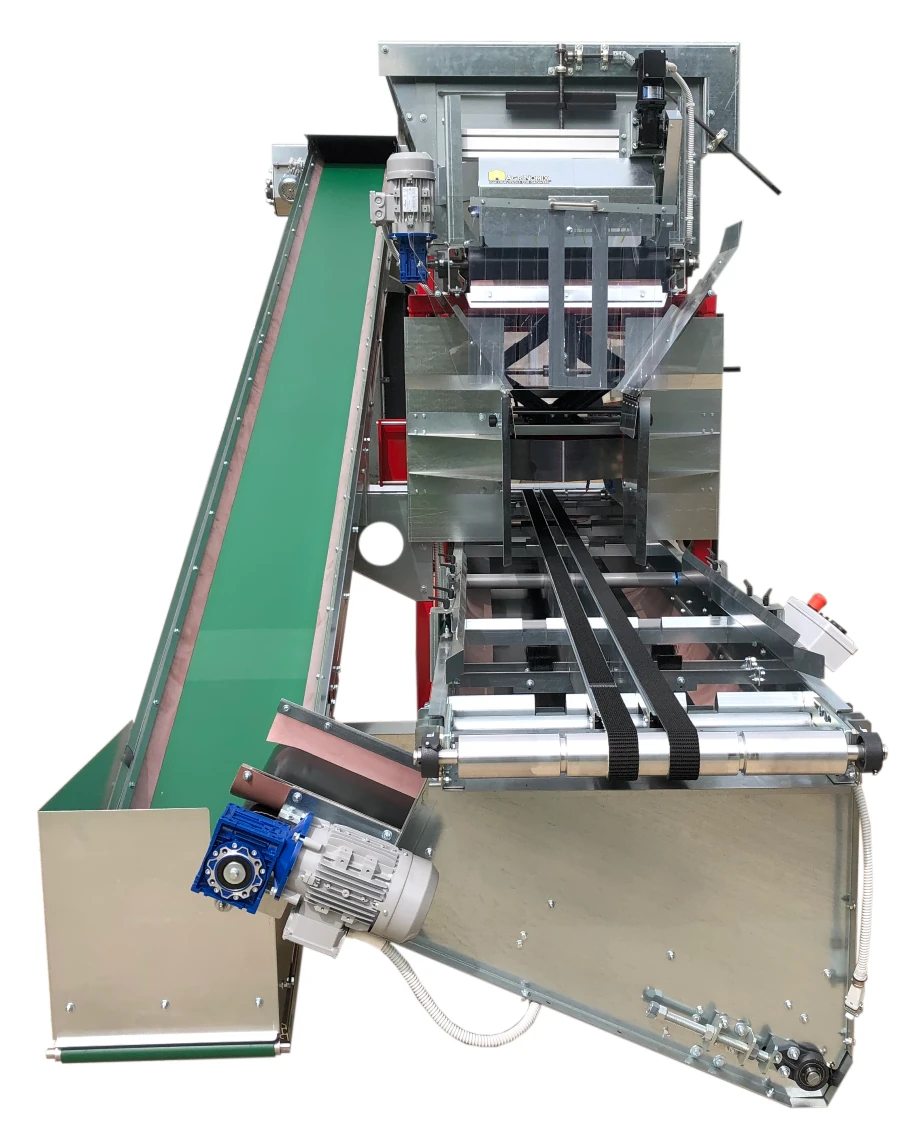

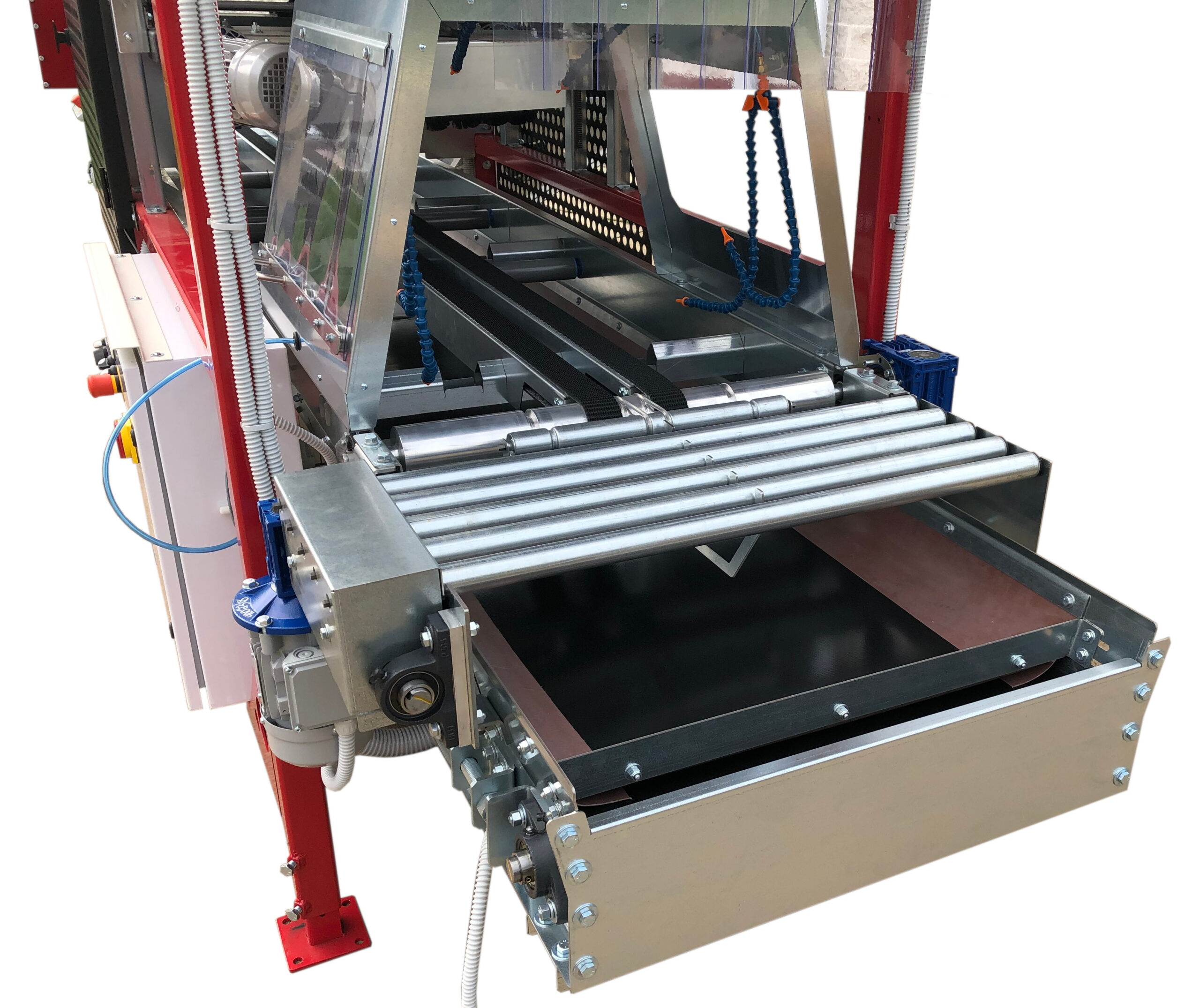

KV-XM Tray and Pot Filler

The KV-XM Tray and Pot Filler is equipped with a 31.5″-wide, heavy-duty, double galvanized elevator chain, this filler can deliver up to a .5 yard of soil per minute. The KV-XM allows you to quickly and uniformly fill trays and pots up to 17.75″ in height. Soil density and compaction are precisely controlled by a longitudinal rotor drop system made up of 4 blades, along with a powered roller, leveling auger, and finishing brush. All are quickly and easily adjusted with crank handles. TheKV-XM Tray and Pot Filler utilizes powered outfeed rollers along with a lower conveyor belt to efficiently return excess soil back into circulation. These features, combined with the high production rates and the reduced maintenance requirements, make this machine a guarantee in terms of optimization of time and resources.