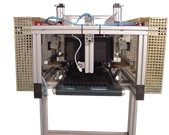

The Multi-Stack Tray Dispenser by Urbinati is a highly efficient solution for automatically dispensing shuttle trays, plug trays, and the innovative new individual packs. These dispensers can function as independent units or be fully integrated into various types of production lines, enhancing workflow and productivity.

Urbinati offers two versions of the plug tray dispensers to meet different operational needs. The “single stack” model requires manual loading of tray stacks, making it ideal for smaller-scale operations or those with limited automation requirements. In contrast, the “multi-stack” version features automatic stack loading via an upper conveyor belt, with the dispensed trays returned on a lower belt, streamlining the entire process.

Both models are designed for versatility and ease of use, with adjustable settings to accommodate a wide range of tray sizes. This flexibility ensures that the dispensers can be adapted to various horticultural needs, providing a reliable and efficient solution for any growing operation.

Incorporating the Multi-Stack Tray Dispenser into your workflow can significantly reduce labor costs and increase efficiency. These dispensers’ advanced automation capabilities make them an essential tool for modern horticultural operations aiming to optimize their tray handling processes and boost overall productivity.

Request a quote for pricing info