RP Template Filler

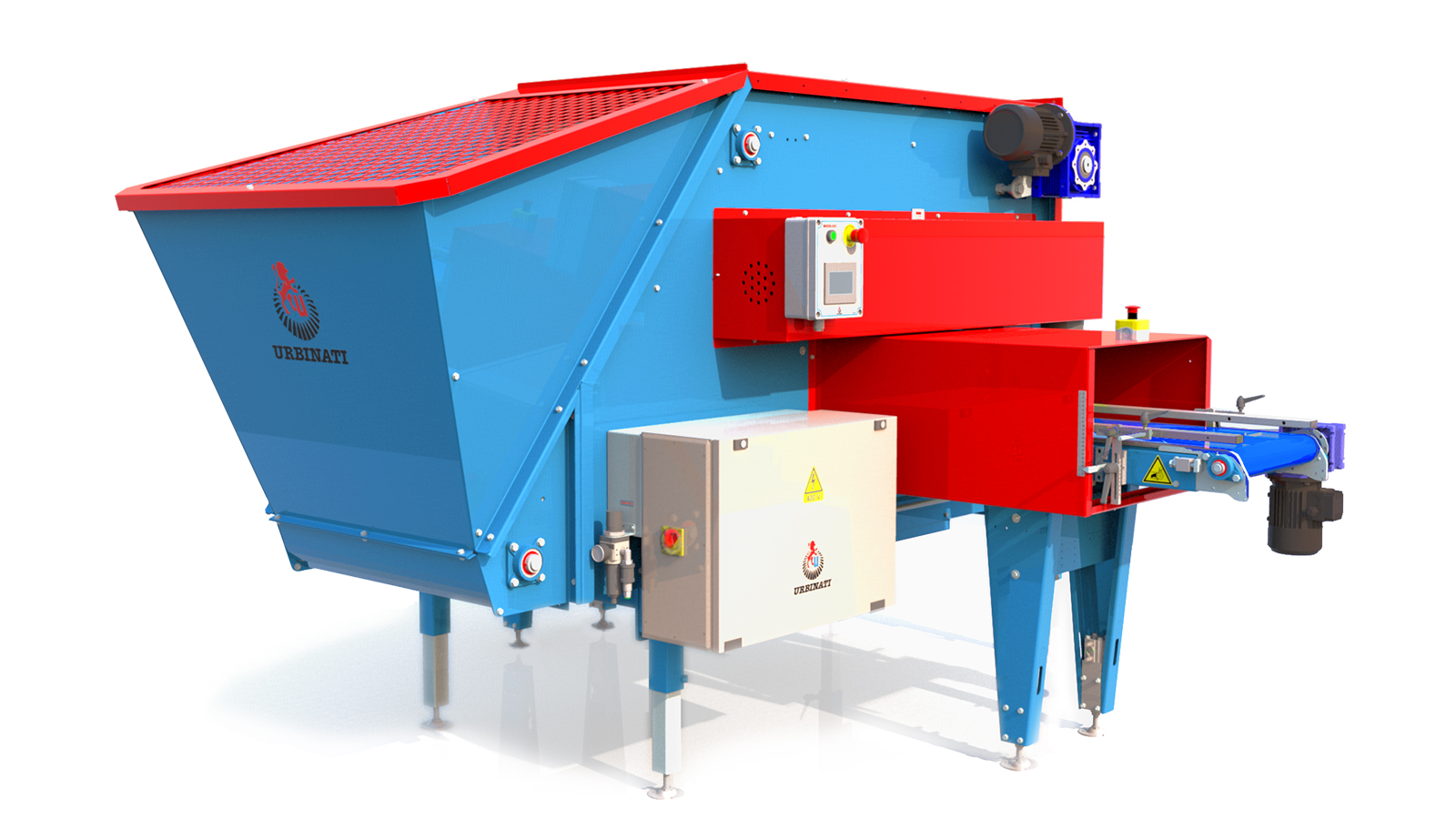

Designed to meet customer specifications, the RP Template Filler ensures uniform, waste-free soil filling. A cross-rotor with steel blades controls its adjustable soil density and compaction. Key functions such as speed, blade rotation direction, and number of passes are managed by a user-friendly, programmable PLC system, easily accessible via a touch screen.

What sets this Template Filler apart is its adaptability to different container types without needing to adjust the working height of the infeed belt. The machine’s central unit can automatically modify the filling height based on parameters entered through the touch screen. At the same time, the conveyor belt remains at a fixed height—perfect for seamless integration into a production line.

Additionally, the RP Template Filler’s unique design keeps mechanical components isolated from soil contact, resulting in a more predictable maintenance schedule ensuring long-term efficiency. This combination of advanced technology and minimal upkeep makes the RP Template Filler a reliable, high-performance choice for any horticultural operation.

RP Template Filler Features

- 550-liter hopper capacity, available on both the right and left sides of the conveyor belt

- Fixed height feed belt; central unit adjusts height to match container size

- Remote control with color touch-screen panel for flexible operation

- Double-chain soil elevator.

- Electronically adjustable container height.

- Custom-made masks for precise container filling

- Vibrating table with fixed or adjustable speed, integrated with the conveyor belt

- Multi-container filling device, capable of filling multiple containers simultaneously (up to 600 mm width)

| Specifications |

| Hourly Production |

600 containers/hour |

| Hopper Capacity |

500 l |

| Container Maximum |

600×400 mm |

| Container Maximum Height |

200 mm |

| Power |

5 kW |

| Weight |

1600 kg |